savings vs reefers

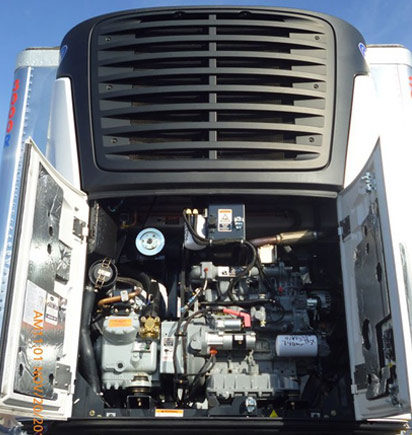

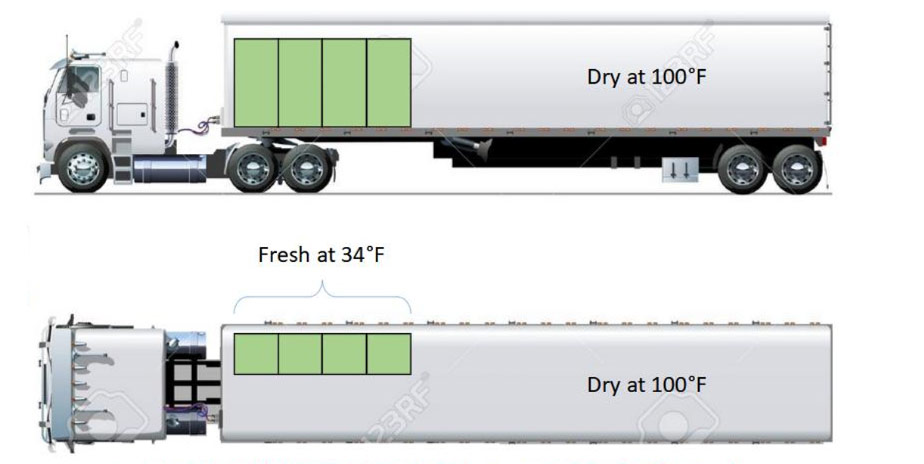

To avoid any possible confusion, we are talking about this guy at display in the following picture.

First let´s examinate closely all costs involved in running a reefer trailer, then we will compare it with dry trailer, and then we will add few Industrial Coolers.

To start if you want to purchase a new 53 feet reefer trailer you are looking to an investment of around 90.000 $USA, maybe a bit more depending of the state where you are located.

Once you buy it, you have an operating and maintenance cost, both in most cases

underestimated or mistakenly considered lower of what they are.

Let’s look at the two-mayor operating cost, being the first one diesel consumption.

The following may be shocking for some readers but these Reefers units most times are self-powered, and how do they achieve that? Easy: typically, it has a small four cylinders diesel engine inside; which, by the way, is not so small, see next picture:

The mechanism is clear: a diesel engine that moves a compressor to get the needed cold from the unit to keep the products refrigerated or frozen. Very similar to the engine of your car, moving one compressor for your air condition to work, so you are comfortable inside.

Any thoughts on how much diesel this peculiar engine drinks? Well, that depends in several factors like how old or new is your unit, how well maintain is, how hard are the external weather conditions, how good is the thermal insulation of your trailer, and how smart and discipline the driver is. Whatsoever everybody seems to agree to the following range, ready for a surprise?

Between 0.4 and 1.1 gallons per hour.

Being the average 0,75 gallons per hour.

This is the reason why Reefer trailers have a separate diesel tank; most models are 25 or 50 gallons.

Well, is easy to understand that when a Reefer is loaded with products and hits the road the diesel engine will be working 24 hours, no matter if the truck is stopped, until the cargo is delivered destination.

But regardless of the previous reality, let’s make a small quick calculation if the unit works 10 hours a day, 5 days a week and only 50 weeks a year.

Then we get 10 x 5 x 50 = 2,500 hours yearly.

What means 2,500 hours x 0.75 gallons per hour = 1,875 diesel gallons yearly.

Moneywise at a quick average of 4.00 $ a gallon we get: 7,500 $ a year.

The second mayor operating cost is: that because this is a very complicated machine, you need a certify driver which cost you a lot more than a normal driver. Being in 2.024 the following numbers:

Average weekly pay dry trailer driver: 1,400 $

Average weekly pay reefer trailer driver: 2,040 $

Weekly difference: 640 $

Monthly difference: 2,560 $

Year difference: 30,720 $

Now let´s see the two major maintenance cost, being the first one the periodical reefer technician that is required to perform regular service, as per most manufacturers recommendations this should be done each 1.000 hours of machine work. Since Reefer average is 5.000 hours a year, this means 5 technical visits, which cost 250$ an hour with a minimum of 2 hours charge (could be more) but let´s be humble 500$ each visit.

Technical service cost a year: 2,500 $

The second major maintenance cost is the medium repairs, except the first year of a new unit, all the rest of the time you are going to face at least one fixing job a year, with an average cost of 2,000$ each.

Life expectancy of a reefer trailer is 40.000 hours, with average use of 5.000 hours a year that is 8 years; but the refrigeration unit last half of it, meaning 20.000 hours, so in the year four you will be forced to decide if do a major rebuilt to that machine or purchasing a new one, either case you are looking at a 20,000 $ bill in that moment.

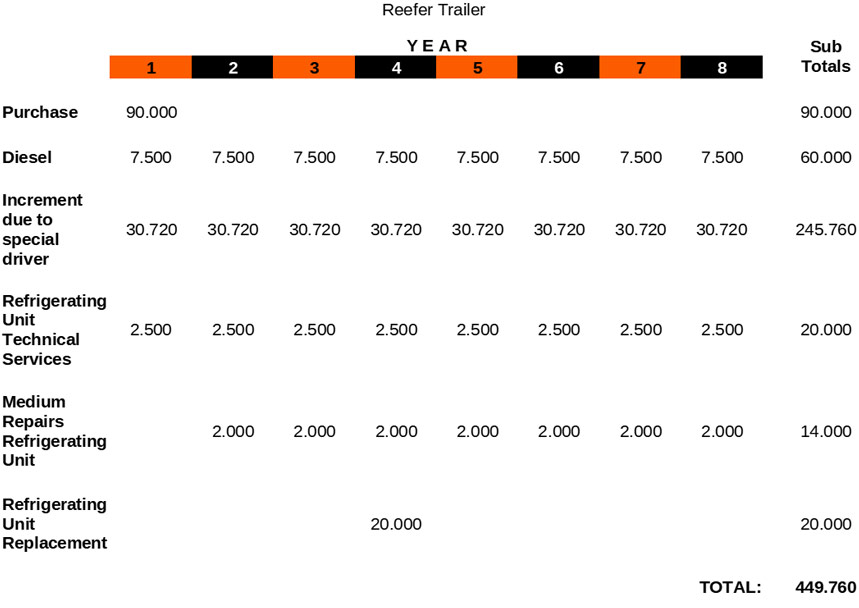

We believe that at this point you are starting to get the idea that reefers are very expensive machines, see all number together in an 8 year table.

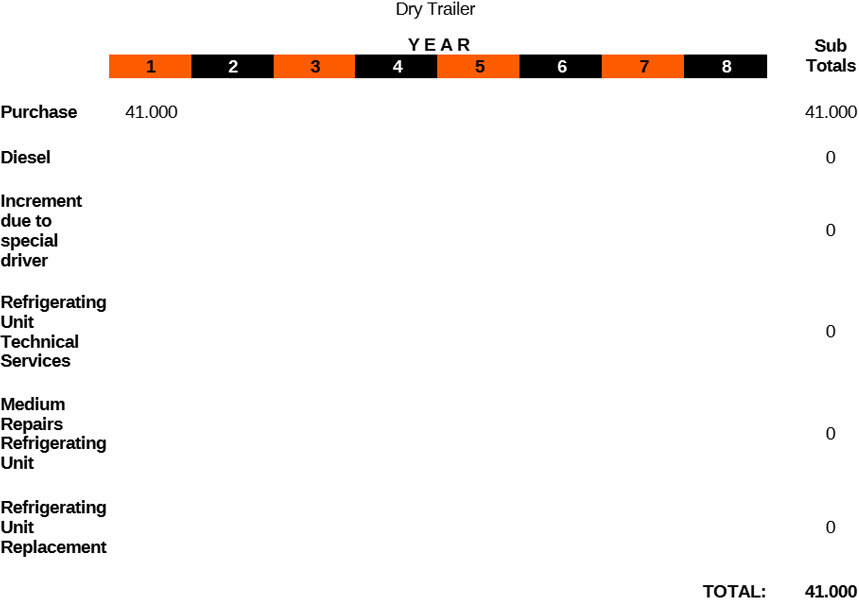

Well now if we do the same analysis to a 53 feet dry trailer, we have:

And because the dry trailer does not have any refrigerating unit, all the costs related to it just disappear.

See the result in the same 8 years table:

So now you know that the actual difference between a dry and a reefers trailer, in a period of 8 years’ time, is around 400.000 $. So, you better be wise which option you choose.

Until now most people think: “well I know reefers are expensive and complicated, but if I need to move frozen or fresh I have no choice” …. wrong!!! that was the previous ancient paradigm.

Please, don´t get us wrong, there are many excellent Reefers brands in the market, and they do a magnificent job, their engineers spent countless hours trying to be more efficient and clean every day, and so far, they have done for all of us a great service moving the refrigerated and frozen goods around, our respects and congratulations to all of them.

But, regardless of the previous fact, we would humbly like to call the attention that in many scenarios there is a much more efficient, cost effective and clean way to move refrigerated or frozen products around, and that is using our Industrial Coolers.

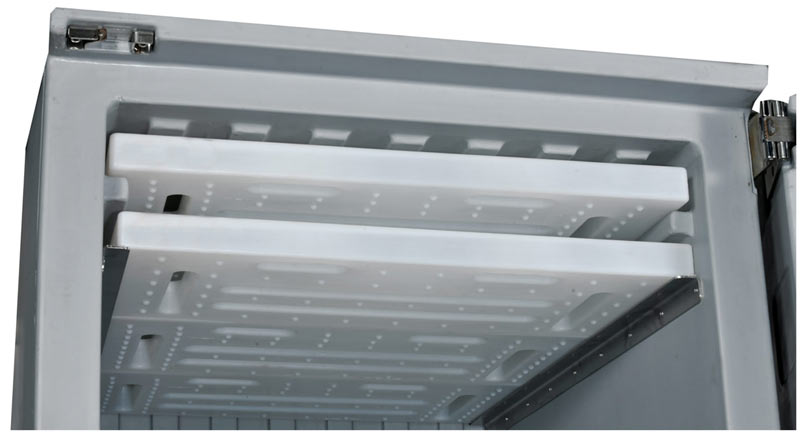

Please, allow us to explain, many readers will fall into the tentation to think that they know what a “Cooler” is and stop reading here, we warrantee you that our “Industrial Cooler”, and we made the remark in the word “Industrial”, are something that we are pretty sure almost none of the readers had ever hear about.

Our Industrial Coolers are a big box, built by rotomoulding techniques, with an extremely strong heat insulation in their walls, that makes almost impossible for any heat to reach inside to the products, but even the little heat that gets in it is catch by our Industrial Icepacks.

Ice Packs are ready to be reused over night in only 8 hours.

The combination of these two elements, in a wise manner, provide you a mean to transport a refrigerated or frozen product for many hours in a conventional dry trailer without using any energy on the road, no electrical parts, no diesel engine, no dry ice and no normal ice.

Industrial Coolers?

Well, if you have a full load of 26 pallets to completely fill up 100% space inside a Reefer trailer then the conventional Reefer trailer is always the best choice.

The problem comes when that number starts to decrease, or you need to move a mix of products, many of them dry ones and few refrigerated. For example: let´s imagine you have a route that demand 20 pallets of dry products and 4 of fresh, what do you do?

Most times the solution to the previous scenery is just hold the fresh and accumulated those products until the number of pallets is high enough to justify the use of a Reefer unit.

Another option is subcontracting separately the transport of those four pallets to a third-party company.

Both cases add incredible organization effort and cost.

Instead, you can have four Industrial Coolers put your fresh product inside and dispatch it inside a regular dry trailer, no more planning headache or any of the Reefer costs.

As a rule of thumb: if you are in a proportion of 20% or less in frozen or refrigerated products and 80% or more of dry, it is always more cost effective and clean use our Industrial Coolers.

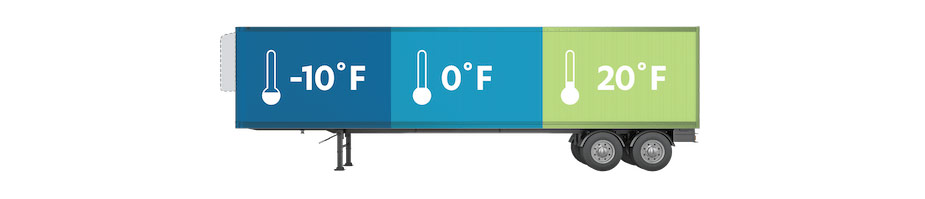

We like to point out that, for this mix temperature situation, some manufactures had created a truck that technical solve the issue, is called “Multi Zone”, see it here below:

They are a very nice technical curiosity but far more complex than a conventional reefer and therefore more costly in all senses.

Just to give you an idea a 28 feet Multi Zone truck 2024 comes at a staggering price of 215.000 $.

And how much is an Industrial Cooler? Well even the biggest model loaded with accessories does not pass the $7,000 budgetary mark. Buy it once and use it for 8 years are least, no operating or maintenance cost.

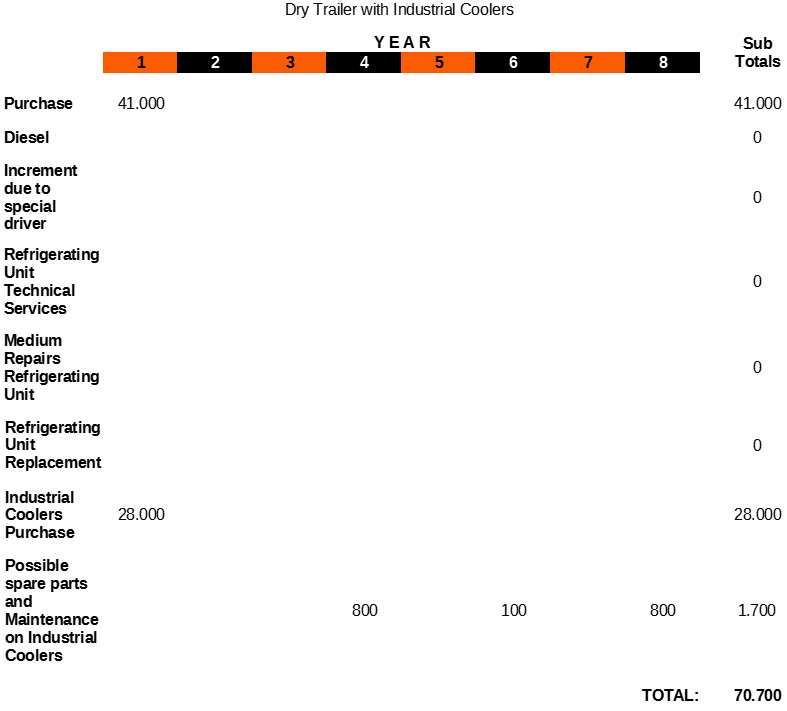

Let´s imagine you get from us 4 Industrial Coolers, so what will be your cost in the same 8 years table?

You sure notice 800$ in the fourth year, that is the door seals, that are easily replaceable, then the 100$ are there just in case you may break a thermometer a hinge or anything of that sort.

Please, do not fall to the false dichotomy that one option is 100% good or bad, actual life includes 1000 shades of grays in between, and therefore every Operation VP must analyze in detail with their Transportation Managers and drivers the solutions or mix of options that best suits their needs.

We let each reader think about it.