EMISIONS VS REEFERS

How and when Industrial Coolers can eliminate the Carbon Foot print of the Reefers

Many readers are familiar with those big trucks transporting refrigerated or frozen products on the roads Wordwide, they look similar to the next picture:

Let’s give a closer look to this guy, sure notice the inmense unit at the front, that for the lay person is associated with a kind of very special air condition system, that is rigth, it is a refrigeration unit ussualy called Reefer. See it closely in the following pictures:

Many believe that this particular unit some how is connected to the truck that move that trailer, in order to get energy to work, because most people associate it with air conditions at home that you plug to the electrical grid, so this one sure needs power that must come from a small generator in the truck pulling it. Wrong!

The following maybe shocking for some readers but these Reefers units most times are self powered, and how do they achieve that? Easy: typically it have a small four cylinders diesel engine inside; which, by the way, is not so small, see next picture:The following maybe shocking for some readers but these Reefers units most times are self powered, and how do they achieve that? Easy: typically it have a small four cylinders diesel engine inside; which, by the way, is not so small, see next picture:

The mechanism is clear: a diesel engine that move a compressor to get the needed cold from the unit to keep the products refrigerated or frozen. Very similar to the engine of your car, moving one compressor for your air condition to work so you are confortable inside.

Any thoughs in how much diesel this peculiar engine drinks? Well that depens in several factors like: how old or new is your unit, how well maintain is, how hard are the external weather conditions, how good is the thermal insulation of your trailer, and how smart and discipline the driver is. Whatsoever everybody seems to agree to the following range, ready for a surprise?

Between 0.4 and 1.1 gallons per hour.

Being the average 0,75 gallons per hour.

This is the reason why Reefer trailers have a separate diesel tank, most models are 25 or 50 gallons.

Well is easy to understand that when a Reefer is loaded with products and hits the road the diesel engine will be working 24 hours, no matter if the truck is stop, until the cargo is delivered at final destination.

But regardles of the previous reality, lets make a small quick calculation assuming that the unit works 10 hours a day, 5 days a week and only 50 weeks a year.

Then we get 10 x 5 x 50 = 2,500 hours yearly.

What means 2,500 hours x 0.75 gallons per hour = 1,875 diesel gallons yearly.

Ever wonder how much CO2 emissions in a single diesel gallon?

Staggering 22.44 pounds (10,180 grams) of CO2 per each gallon!

Last math of the article, we promise.

1,875 gallons x 22.44 pounds = 42,075 pounds !!!!

Like metric better:

1,875 gallons x 10,18 Kg = 19,087.50 Kg just a bit over 19 metric tonnes !!!!!

And this is every year for every active Reefer unit out there.

Only in USA, the stimated is: that total active Reefers units are around 500.000, and 70.000 new units are sold every year, of course the oldest ones also gets scraped.

Please, don´t get us wrong, there are many excellent Reefers brands in the market, and they do a magnificent job, their engineers spent countless hours trying to be more efficient and clean every day, and so far they have done for all of us a great service moving the refrigerated and frozen goods around, our respects and congratullations to all of them.

But, regardless of the previous fact, we humbly like to call the attention that in many escenarios there is a much more efficient, cost effective and clean way to move refrigerated or frozen products around, and that is using our Industrial Coolers.

Please, allow us to explain, many readers will fall in to the tentation to think that they know what a “Cooler” is and stop reading here, we warrantee you that our “Industrial Cooler”, and we made the remark in the word “Industrial”, are something that we are pretty sure almost none of the readers had ever ear about.

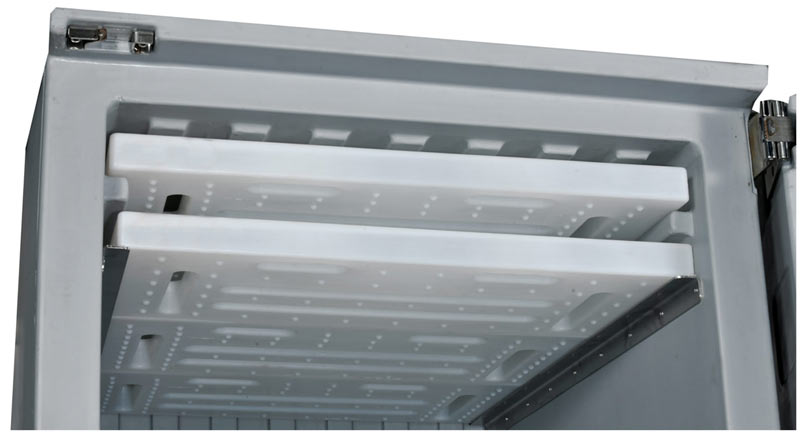

Our Industrial Coolers are a big box, built by rotomoulding techniques, with an extremelly strong heat insulation in their walls, that makes almost impossible for any heat to reach inside to the products, but even the little heat that gets in it is catch by our Industrial Icepacks.

Ice Packs are ready to be reused over night in only 8 hours.

The previos explanation, is the reason why we said: that compare to a Reefer unit our Industrial Coolers are free of any carbon foot print, cero, nothing, nada!

When it is best to use our Industrial Coolers?

Well if you have a full load of 26 pallets to completely full up the 100% space inside a Reefer trailer then the conventional Reefer trailer is always best choice.

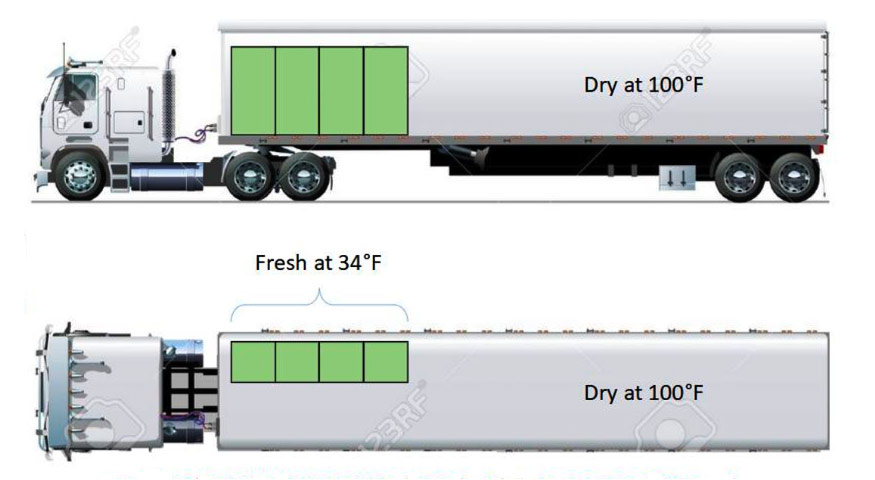

The problem comes when that number start to decrease, or you need to move a mix of products, being many of them dry ones and few refrigerated. For example: let´s imagine you have a route that demand 20 pallets of dry products and 4 of fresh, what do you do?

Most times the solutions to the previous escenary is just hold the fresh and accumulated those products until the ammount of pallets if high enough to justify the use of a Reefer unit.

Another option is sub contract separatly the transport of those four pallets to a third party company.

Both cases add incredible organization effort and cost.

Instead you can have four Industrial Coolers put you fresh product inside and dispatch it inside a regular dry trailer, no more planing headache or Reefer cost.

And you will move your fresh product with CERO carbon emission on the road for keeping the cold.

As a rule of thumb: if you are in a proportion of 20% or less in frozen or refrigerated products and 80% or more of dry, it is always more cost effective and clean use our Industrial Coolers.

And more over in many places new legislations allows companies to claim reduction in taxes each time that they adquire new technologies to reduce carbon emission.

Please, do not fall to the false dicotomy that one option is 100% good or bad, actual life includes 1000 shades of grays in between, and therefore every Operation VP must analize in details with their Transportation Managers and drivers the solutions or mix of options that best suits their needs.

But we have a dream… imagine we can switch only 5% of the Reefer, that means 25.000 trailers, and work out those cases with Industrial Coolers, then we will have achieved the staggering carbon reduction of:

25,000 Trailers x 19 metric tonnes = 475,000 metric tonnes CO2 reduction !

Almost half million metric tonnes of carbon reduction! And that is each year! Imagine we do so during 5 years or more.

And this is a win, win, win and win situation; the company wins because saves money, the products wins because they got a better cold chain protection, the country wins because we depend less on fossil fuels and the planet wins too.

Is it 5% to much to ask? We let each reader to think about.